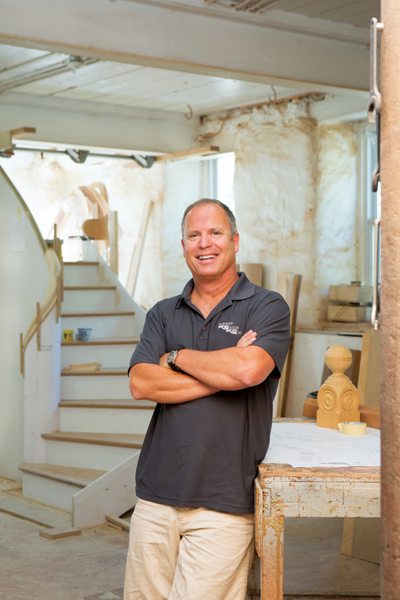

Five Questions: Bill Bivona

January 22, 2018

Bill Bivona, of Hardwood Design, explains the challenges and rewards of designing and building staircases.

Text by Robert Kiener Photography by John Soares

(1) Staircase making is a rather specialized trade; how did you get into it?

(1) Staircase making is a rather specialized trade; how did you get into it?

I always wanted to be a furniture maker, but I soon discovered that, to make a living, I had to subsidize my furniture making with other projects, such as building kitchen cabinets. A client asked me to build a staircase, and I was attracted by the challenge. Other orders for staircases followed and, although the first few projects were a huge learning curve, I realized that stairs were the way to go. We made a decision to just focus on stairs because there was a real need in the market. We have the space—20,000 square feet—the special tools, and a staff of twenty highly accomplished craftspeople. I like to tell the story of driving up to a job site with a 1,500-pound circular stairway. Everyone stops to lend a hand. Typically, after we heave the stairs into the opening, all these other incredibly talented people slap us on the back and say, “I wish I could work with you guys because you do the most challenging part of the job.” There is a huge amount of respect for what we do among the woodworking trades.

(2) What are some recent trends in staircase design?

There is a trend to use a lot of metal and glass, which we hate (laughs) because we are woodworkers. Kidding aside, it is a clean, sleek, contemporary trend we see a lot of demand for. To complete these projects, we work with glass contractors, metal fabricators, and metal finishers. These contemporary designs, which look very clean and simple, are ten times more difficult than the traditional wooden designs where you can make up any irregularity with the trim. With contemporary staircases, if you are chasing an eighth of an inch in an object that goes two or three stories, it’s a real challenge to get it exactly right. Another trend we see is that clients are interested in being greener by using reclaimed lumber and more rustic-grade lumber in staircases.

(3) How has technology changed your industry?

We used to get on our hands and knees and lay out a circular stair on a floor

with sheets of plywood, using a big trammel points compass, straightedges, and flexible battens. Now we do everything on screen and toggle back and forth between different designs. The design part of the process is much easier and more efficient. Also, with AutoCAD you can send a schematic layout or a 3-D model to the client in an instant via email. We can also take our drawings or the models and convert them to Computer Numerical Control (CNC) machine language to cut and shape many of the pieces down to accuracies of 1/1000th of an inch.

(4) But craftsmanship is still a key part of building stairways?

Definitely. Take, for example, the creation of wreathed, or curved, handrails. This is still an art. While a certain amount of cutting can be done on the CNC machine, wreathed handrails are largely laid out and hand carved from a solid block of wood. Our guys use pneumatic grinders and die grinders as they whittle away the wood. In effect they are sculptors. When you are gliding your hand along a continuous handrail, it really has to feel seamless, and there’s an art to achieving that.

(5) Are there any common misconceptions about staircase design and building?

People see these opulent staircases in, say, an old Newport mansion, and they don’t think they can get these today because the craftsmanship or specialized skills don’t exist. But they do, and we are proof of that. We can duplicate the great majestic stairways of a century ago and, thanks to today’s materials, we can make them even more accurate and more durable. | Hardwood Design, Exeter, R.I., (401) 294-2235, hdistair.com

Share

![NEH-Logo_Black[1] NEH-Logo_Black[1]](https://b2915716.smushcdn.com/2915716/wp-content/uploads/2022/08/NEH-Logo_Black1-300x162.jpg?lossy=1&strip=1&webp=1)

You must be logged in to post a comment.